Jerry E. Howell Model Project Plans & Kits

Outpost Enterprises, LTD - 695 Godfrey Road - Hollansburg - Ohio 45332 - USA

(World Wide Supplier of Quality Model Project

Plans & Kits Since 1992)

"Howell V-Four" Engine Camshaft Assembly

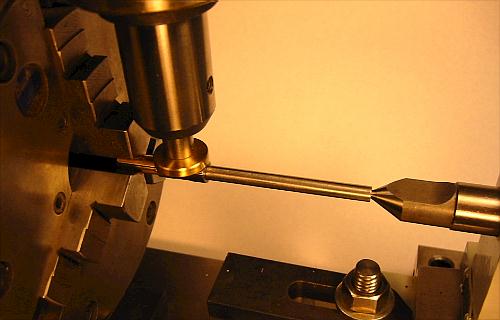

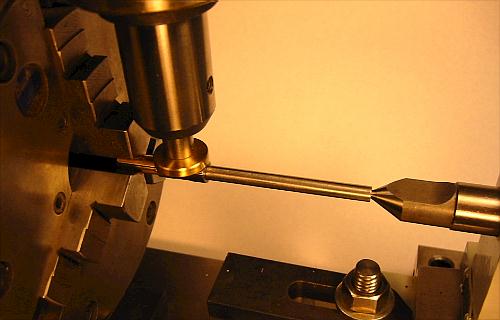

Center the cam shaft under the mill spindle. A 5/8"

long split bushing flush with the end of

the shaft accurately spaces the first cam pair. This is the gear

end of the shaft. The rotary

table degree setting is set to zero. With Loctite on the shaft,

the proper cam pair is twisted

on the shaft and with the lobes on top. The exhaust lobe will

be against the split sleeve and

pointing away from you. The Cam Setting Tool is brought down to

accurately set the 'zero'

line across the lobes. Let the Loctite set 15 minutes.

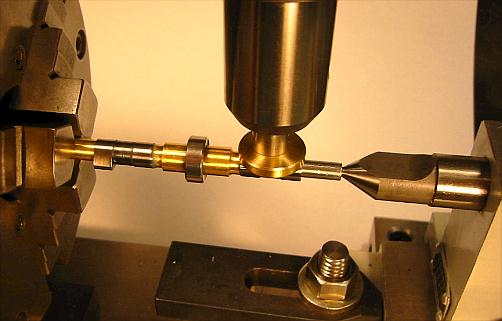

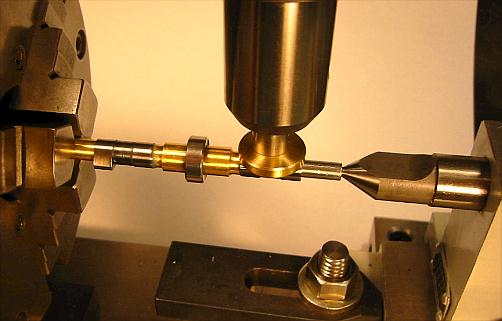

Dial the rotary table 180 degrees. Retract the tail center and

using Loctite, install

bearing spacers and center bearing. Install the cam pair as before.

The exhaust lobe

will be facing the tail center and pointing away from you. Bring

the tail center back

up and set the cam pair 'zero' line as before.

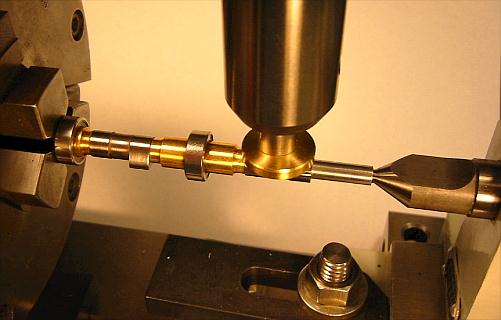

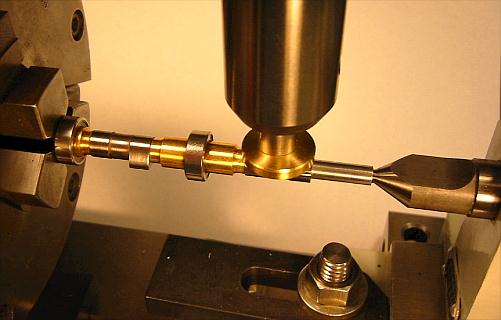

Remove the split sleeve and reverse the shaft in the 3-jaw chuck.

Leave the chuck

jaws just a little loose and 'zero' the first cam pair, then tighten

the chuck jaws. In

the photo, I should have left the radiator end bearing off untill

later.

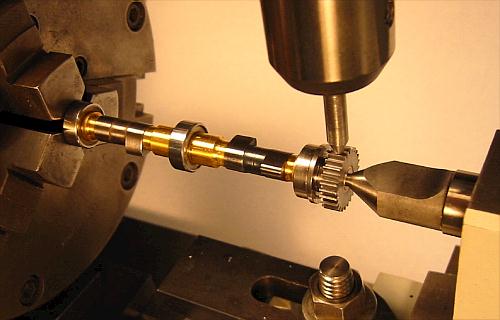

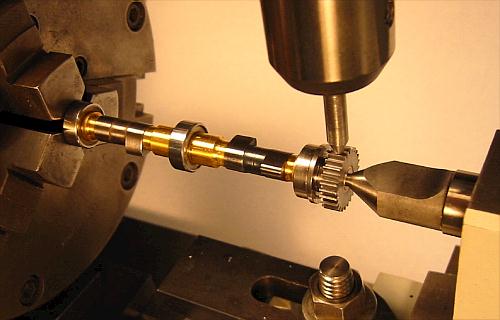

Rotate the rotary table either 3.4 degrees (3 degrees 24 minutes)

or 6.9 degrees

(6 degrees 54 minutes) depending on which shaft you are doing.

Make a timing punch

mark at a tooth of the gear as shown on plan sheet #28. Count

the number of teeth

clockwise depending on which shaft you are doing and scribe a

line between the next

two gear teeth for later identification. Change from the Cam Setting

Tool to the Gear

Setting Tool. Install the spacer, bearing, and then the gear with

Loctite. Rotate the gear

so you can bring the setting tool down between the gear teeth

where the scribed line is.

© Copyright - 2006 - 2007 Jerry E. Howell

- All rights reserved